BELIMO Valves Systems S.R.L. “Soluciones globales para el control de

Author affiliations. 1 Advanced Materials Research and Energy Application Laboratory, Department of Energy Engineering, North Eastern Hill University, Shillong-793022, Meghalaya, India. 2 School of Life Sciences, Assam Don Bosco University, Tepesia Gardens, Assam, India. 3 Department of Electronics & Communication Engineering, IMPS College of Engineering & Technology, Malda, West Bengal, India

24V 010V/420mA Válvula de agua de modulación Actuador eléctrico

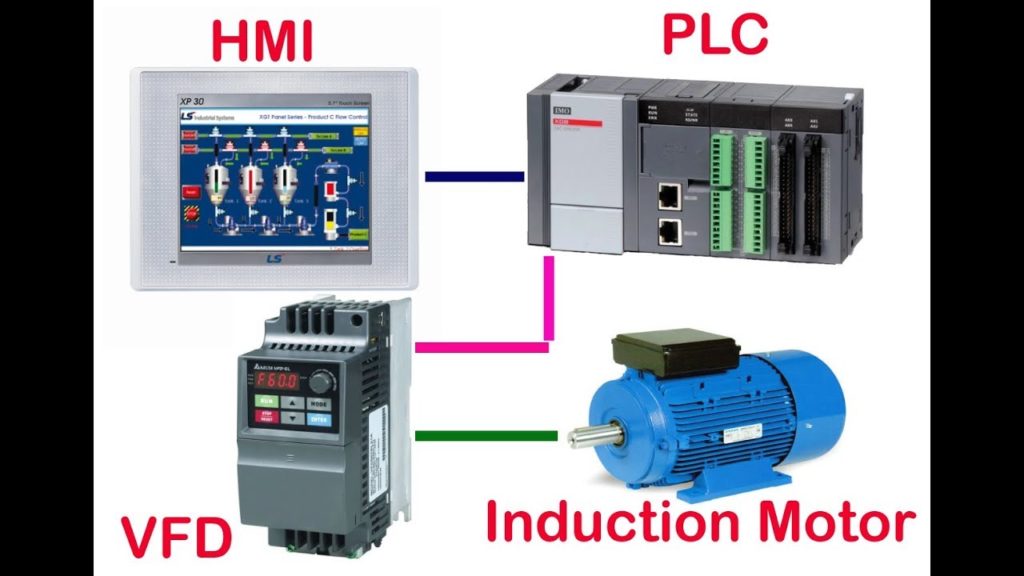

SCADA provides an interface between PLC and the operator. PLC more focused on control functionality. SCADA more focused on visualization and operator interface. PLC can be used to control and monitor specific equipment or machinery. SCADA can be used to control and monitor entire industrial processes over a wide area.

Ejemplo Paso A Paso.. Como Dimensionar Una Válvula de Control PDF

The ControlWave Micro is a highly programmable controller that combines the unique capabilities of a programmable logic controller (PLC) and a remote terminal unit (RTU) into a single hybrid controller. The ControlWave Micro specializes in oil and gas, water and wastewater, and industrial control applications that maximize the performance of a.

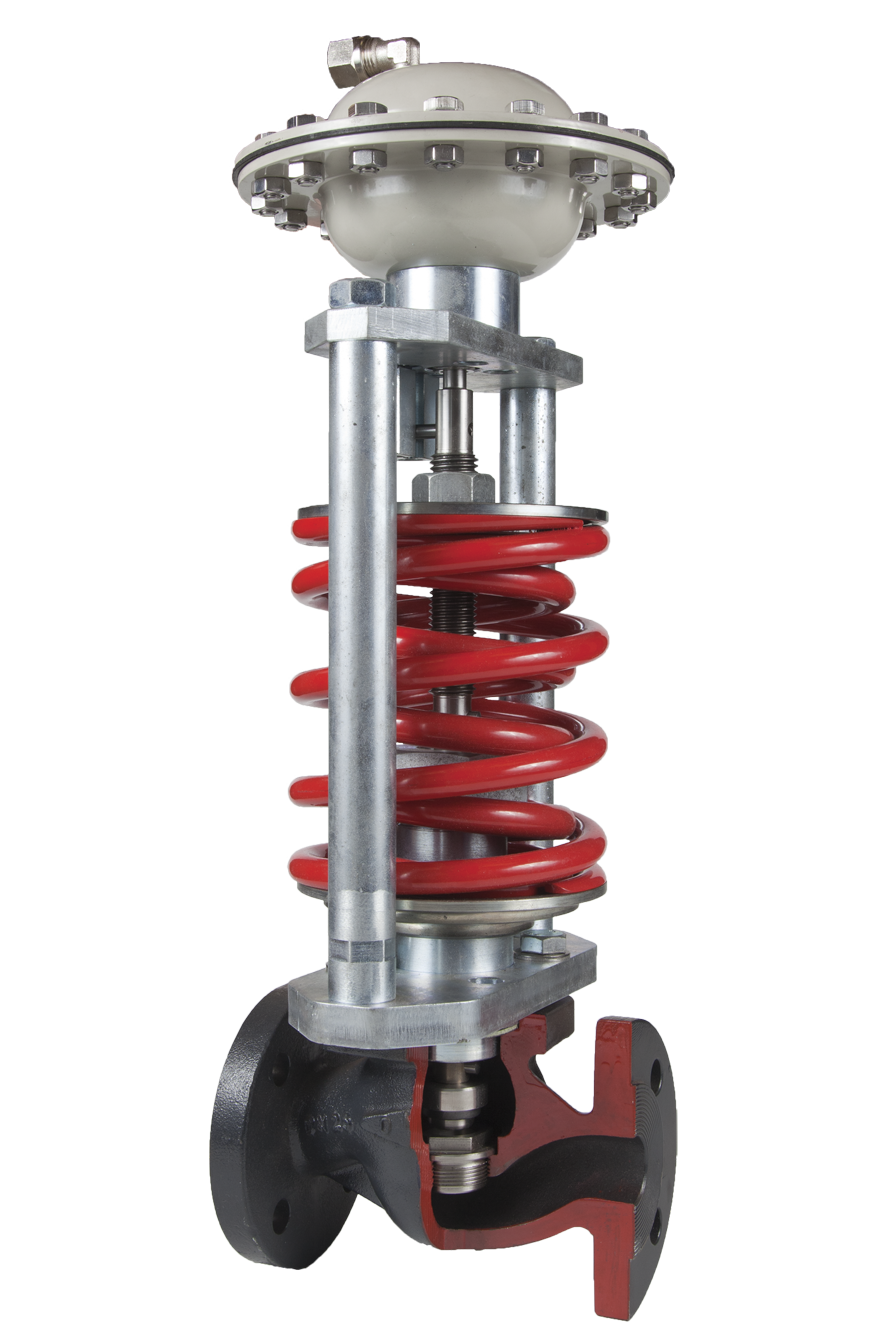

Válvula reductora de presión Modelo M1 Nvsautomatizacion.

To interface PLC with SCADA first we have to establish a proper communication channel. The monitoring PC's communications or network port link is connected with the cable (usually) that connects to the PLC. The next step is to ensure that both the systems can communicate with each other. Atlast you need to set up the SCADA server to collect.

Diseño y funcionamiento de la válvula de control

PLC stands for programmable logic controller. A programmable logic controller is installed to monitor sensors. In this manner, a PLC stands for data collection, receiving critical information about the flow and input within the system. To this end, the PLC will also perform basic interventions, triggering outputs when the parameters programmed.

Autómatas programables PLC en aplicaciones de automatización industrial

SCADA communication protocol. SCADA (Supervisory Control And Data Acquisition) is a system that refers to a combination of telemetry and data acquisition. This consists of gathering information, transferring it back to the control center, carrying out the necessary analysis and control, and then displaying this data on a number of display.

Válvulas de Control modulante por Bola Segmentada (RSeries) PPC Sesco

For more info, get in touch with us today! To get started on your next project please get in touch. +44 (0) 113 2457170. sales@saftronics.co.uk. Saftronics are able to offer a full spectrum of PLC & HMI based systems. We are also a highly respected SCADA developer with many years of experience.

Electrovalvula hidraulica 4/2 doble bobina tamaño 10 cetop 5

SCADA stands for Supervisory Control and Data Acquisition and is a system for monitoring and controlling and as the name implies, data acquisition. It is widely used in factories to monitor and control production lines and machines. A good way to make an understanding, of what a SCADA system is and where it can be used, is to see it in relation.

Electrotec Control de una válvula con PLC 📲 Síguenos en...

Before examining the PLC program, first consider a hard-wired approach. Basic PLC program for control of a three-phase AC motor - for beginners (on photo: Simatic S7-1500 PLC; credit: SIEMENS) The following line diagram illustrates how a normally open and a normally closed pushbutton might be connected to control a three-phase AC motor. In this.

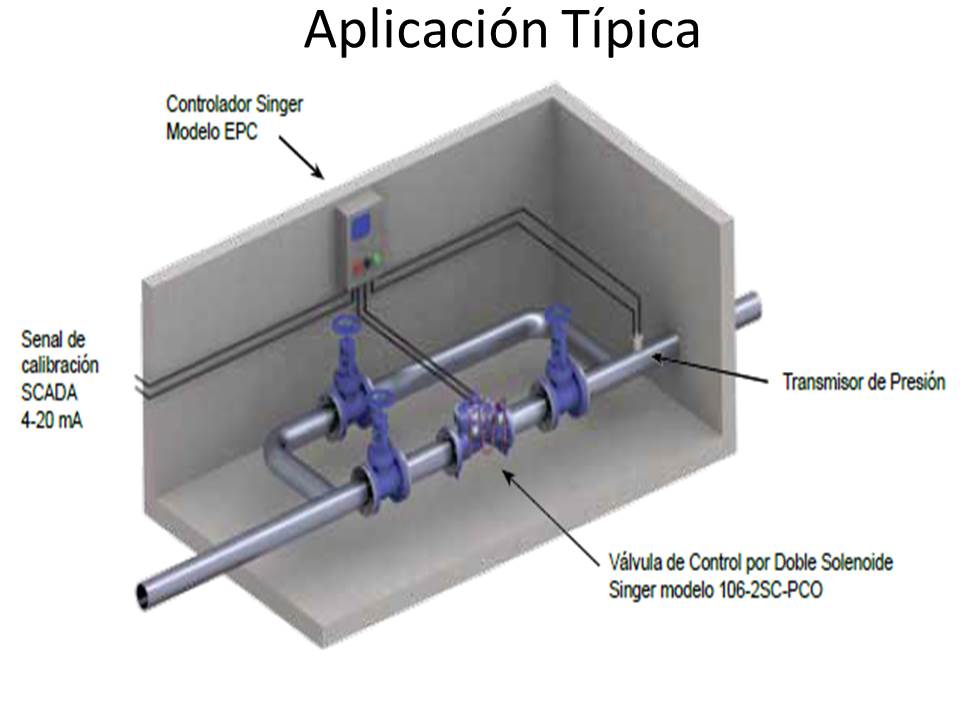

Equipamiento Industrial Válvula De Control por Doble Solenoide para

PLCs have three key features. These include inputs and outputs that send and receive data from those external components, some sort of communication protocol in order to connect to some kind of supervisory control (like SCADA), and a way to interface with the device in real time, typically through an HMI. Learn more about PLCs with our separate.

Equipamiento Industrial Válvula De Control por Doble Solenoide para

After adding a PLC controller, the next step is to configure its ethernet protocol, because we are going to connect PLC with SCADA through ethernet protocol. For that Go to PLC CPU Properties >> General >> Ethernet addresses. The subnet in the ethernet properties in both PLC and SCADA must be common to connect PLC with SCADA.

Electrovalvula hidraulica centro presurizado 4/3 tamaño 6 cetop 3

Three Element Control using PLC, PID & SCADA Interface A

Motor control using PLC HMI VFD Tutorial 3 .2 TEKNIK MEKATRONIKA

Compact modular design of ultra-low power consumption ( below 2W per module on average). Strong environmental adaptability featured with -40 to 80℃ operating temperature range, EMC 3B anti-electromagnetic proof, G3 anti-corrosion proof, 2G acceleration vibration resistance. Mass data capacity with local storage capacity of up to 256MB, and.

VALVULA DE CONTROL Imagen Boletin Industrial

.png)

The difference between them is that the PLC is hardware based and SCADA is software based. While both fall under the category of "control systems", SCADA provides greater capability than the PLC with the help of several components. Optimally, you would want to use the capabilities of both types of control systems in order to meet design.

Válvulas De Control De Globo SIO

Yesterday's SCADA systems relied almost exclusively on analog phone lines. Today, most suppliers use wireless wide-area network (WWAN) communications for at least some segments of the grid. And, the use of public cellular networks in SCADA applications grows each year. This paper discusses the role of cellular communications in SCADA systems.

Todo lo que necesita saber sobre cómo funcionan los actuadores de

The cellular infrastructure can serve as a backbone to integrate and enable communications from SCADA Hosts in the office with remote field assets including: sites with dedicated I/O. RTU / PLC sites with RS-232 interface. RTU / PLC sites with RS-485 interface. Licensed/ unlicensed Point-Mulipoint systems.

.